Introduction to this issue

The first requirement of an intelligent factory is information such as the power consumed by the factory, the quantity of factory equipment produced, etc. Through this information, the utilization rate of equipment, power consumption, etc. can be analyzed, so as to provide a basis for digital management and daily maintenance of the factory, and go further According to these data, it can also provide decision-making reference for the next step of the development of factories and enterprises.

Collect the power, current, voltage, and power consumption of equipment in the factory for a period of time, judge the current equipment status, shutdown, standby operation, and count the number of processing equipment in the current site. The data on the cloud provides a basis for the digital management and daily maintenance of our factory, and provides a reference for factory decision-making.

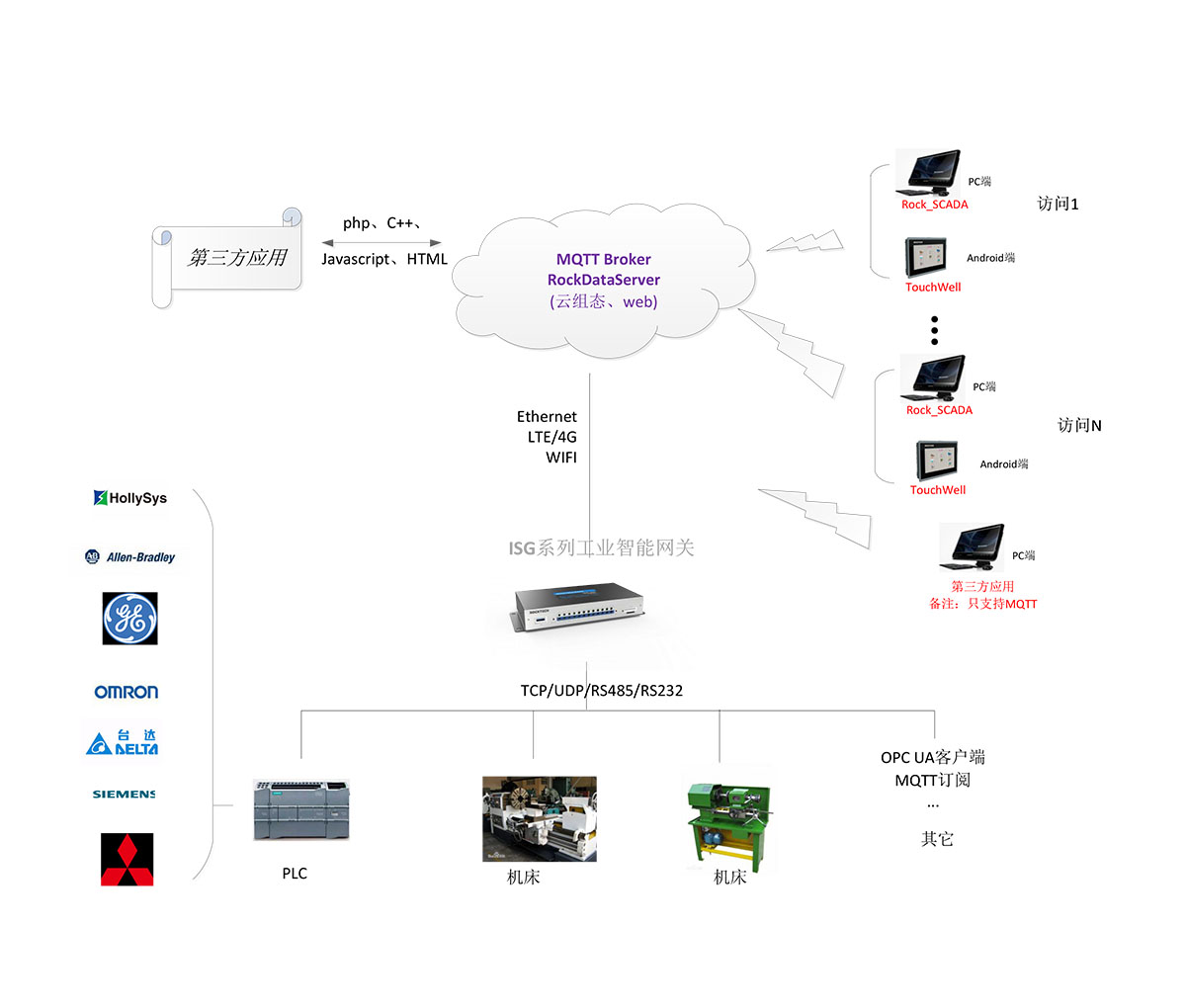

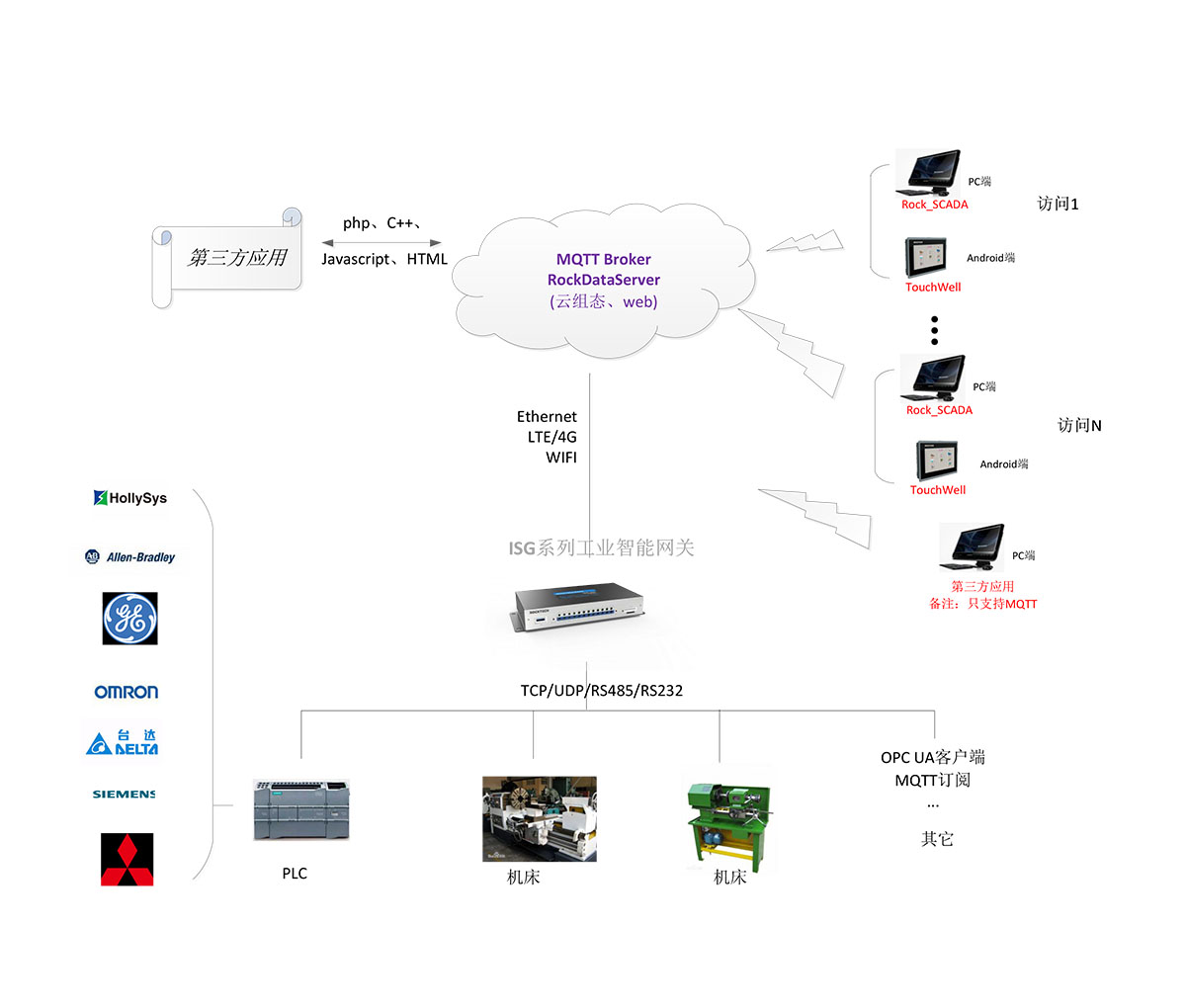

That is, protocol conversion does not mean data going to the cloud, and if the protocol fails, data going to the cloud will be empty talk. Industrial gateways play an important role in data cloud.

The ISG-200 produced by Rocktech not only has built-in 250+ protocols, completes data upload to the cloud, but also supports wide voltage input (9-36V) and judges the current device status (shutdown and standby operation) according to the I/O template data, and provides breakpoints The resume function provides 4-way DI interface, 4-way DO interface and other functions to realize energy consumption monitoring, statistical analysis, alarm and energy usage optimization, and finally complete the entire cycle.

▌▌Accurate and fast data computing ability

The ISG-200 series uses a low-power, high-efficiency processor with a maximum frequency of 900MHz, and a maximum memory usage of 1GB DDR3 and 8GB eMMC. It enables fast data processing and calculation;

▌▌Customized Embedded Linux System

The ISG-200 series can be equipped with a customized embedded Linux system for users. In order to meet the different needs of multiple users, Ruixun can develop customized APPs according to different user usage scenarios and business functions. By calling external interface functions, Customize reasonable solutions for customers;

▌▌Support multiple PLC protocols and smart device communication protocols

Support OPC UA protocol (support SSL/TLS), including client and server, on the one hand, it can read the data of the third-party OPC UA server, on the other hand, it can be used as the OPC UA server to release data;

Can support PLC remote support and remote maintenance;

▌▌Support harsh environment use

The products have passed strict high and low temperature tests, drop tests, aging tests, vibration tests, and salt spray tests to meet the application needs of customers in complex environments;

Embedded with a CPU internal watchdog and a hardware watchdog to ensure the normal operation of the equipment;

▌▌Various network communication methods

The basic model (R01) has two 100M LAN ports and one drawer-type SIM card slot, and the professional model (R02) has five 100M LAN ports and one drawer-type SIM card slot. Customers can choose wireless 3G/4G network to ensure uninterrupted communication. Intermittent;

▌▌VGA display

The professional model (R02) is equipped with a VGA display interface;

▌▌Cloud server exchange function

Support MQTT client protocol (support SSL/TLS), including subscription and publishing, not only can communicate with servers (Broker) such as mosquitto, but also exchange data with MQTT cloud servers such as Alibaba Cloud;

If you want to know more about related solutions, you can contact online customer service, or call 400 602 5060 for detailed information!