Digital Workshop Solution

Time:2023-03-21 Source:ROCKTECH Views:183

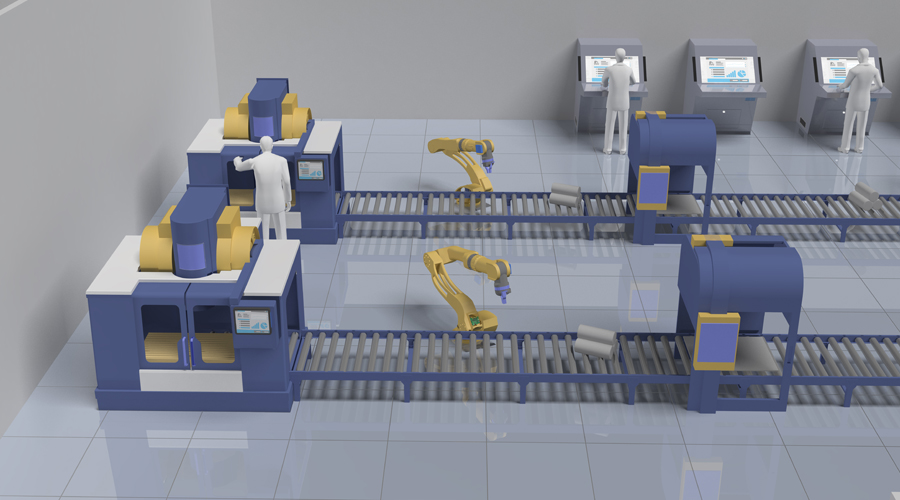

Currently, the accuracy, automation, and added value of equipment in the processing industry are constantly improving, while customer needs have become diverse, which requires manufacturing enterprises to be more flexible and responsive in management to facilitate the use of production resources to create more value. Digitalization of the workshop has guided the direction of manufacturing enterprises.

Based on production equipment, production facilities, and other hardware facilities, the digital workshop aims to reduce costs, improve quality, increase efficiency, and quickly respond to the market. On the basis of optimizing management of process design, production organization, and process control, it designs, manages, and simulates production resources and processes such as "people, machines, materials, methods, environments, and measurements" in a computer virtual environment through digitization, networking, and intelligence Optimization and visualization work, with information digitization and data flow as the main characteristics, provides precise, agile, and efficient management and control of production resources, production equipment, production facilities, and production processes. Digital workshop is the first step of intelligent workshop and an important foundation of intelligent manufacturing.

Currently, the instruments and meters, automatic guided vehicles, computer digitally controlled precision machining and other equipment included in the workshop are controlled by programmable logic controllers (PLC) to execute instructions, and various mechanical equipment or production processes are controlled through digital or analog input and output. At the same time, supported by distributed control systems (DSC) and remote management modules, data can be uploaded to the cloud, thereby achieving workshop level production process execution management systems (MES), manufacturing data and process systems (MDC), distributed numerical control management (DNC), flexible manufacturing systems (FMS), and enterprise level product lifecycle management (PLM), product data management (PDM), customer relationship management (CRM), enterprise resource planning (ERP) Supply Chain Management (SCM), Warehouse Management (WMC), Call Center (CC), etc. form the entire intelligent manufacturing chain.

In this process, there are many manufacturers of on-site automation equipment in the workshop, with different protocols. It is particularly important to translate the industrial protocols of various manufacturers, form a unified private protocol, and ensure accurate transmission and network security. Intelligent industrial gateways are created to meet this demand.

Ruixun Technology's ISG series of intelligent industrial gateway products have formed a "entry-level, standard-level, high-end, and visual" intelligent industrial gateway echelon product based on the needs of different scenarios in digital workshops, dedicated to the comprehensive implementation of industrial protocol resolution, data cloud, and data security functions.

If you would like to learn more about the relevant solutions, you can leave your contact information for detailed information.